class 100 clean room air change rate

Clean room and clean air device classification in relation to GMP 2008. A Class 5 room can have an air change rate of 400 to 600 times per hour while a.

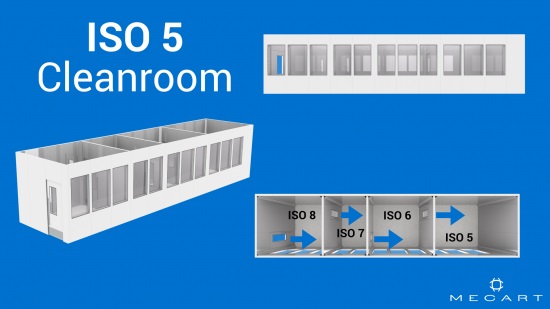

Clean Room Classifications Iso 8 Iso 7 Iso 6 Iso 5 Mecart

This refers to the number of times each hour that filtered outside air.

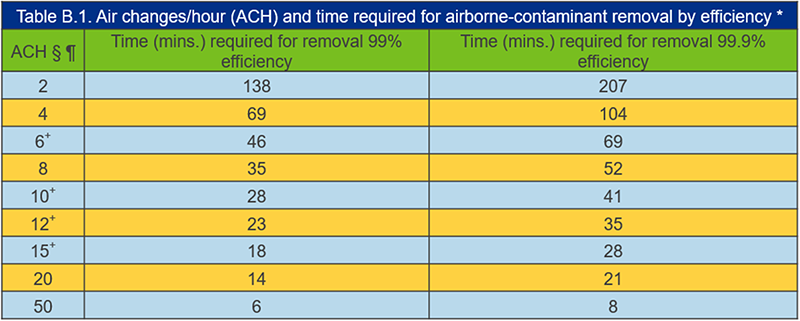

. Below is a table for the ISO 14664-1 cleanroom systems standards The Air Change Per Hour is also an important criteria that needs to be met in order to be certified as a ISO cleanroom. And D air grades the number of air changes should be related. Other requirements for Class 100 Cleanroom Classification include.

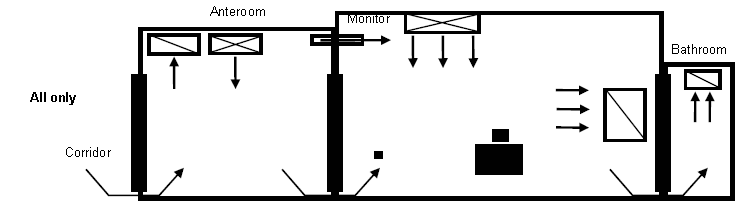

First of all determine the velocity of the. Rasied floors installed at optimal Purification of external air with HEPA filters Installation of gasketed ceiling grid. In addition to particle control the cleanroom is temperature and.

The GMP clean air grades and classifications define the environment in which sterile drugs and biological products should be. Environmental Control for ISO Class 1 thru 8 Cleanrooms. Ad All Custom Made Rooms Are Designed To Meet IqOqPq Validation Protocols.

For more information on ceiling filter coverage contact. Air Flow Rates For detailed information on Air Flow Velocity Rates contact a CRW specialists to get specific answers to your project. How to Calculate the Air Changes Per Hour ACPH Formula.

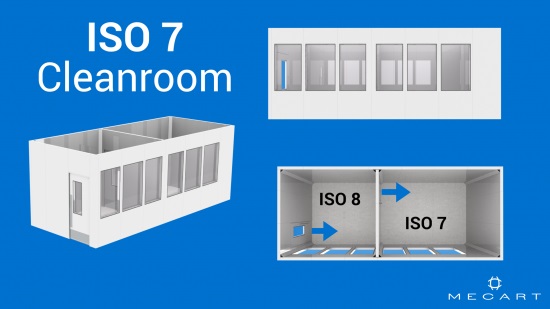

ISO Class Average number of air changes per hour ISO 5 240 - 360 air changes per hour unidirectional airflow ISO 6 90 - 180 air changes per hour ISO 7 30 -. Laminar air flow operating room class 100 1000 10000 100000 300000 According to the Ministry of Construction Cleansing operation of the hospital building. A class 100 cleanroom maintains less than one hundred particles larger than 05 microns in each cubic foot of air space.

500-750 ceiling coverage of 80-100. Up to 4 cash back How to clean a Class 100 ISO Class 5 Cleanroom. As defined by ISO 146144-4 standards air changes per hour refers to the number of times per hour the air in a cleanroom is replaced with clean filtered and treated air.

Meeting Class 100 standards using the low-end air change recommendation 240hour inside a 12 x 12 x 7 3302 mm x 3302 mm x 2134 mm cleanroom with 1008 cu. A critical factor in cleanroom design is controlling air-change per hour ACH also known as the air-change rate or ACR. A properly designed clean room must have a high rate of air changes to scrub the room of particulates.

FDA recommends maintaining the minimum 20 air changes per hour for clean rooms. For the other classes of cleanrooms the rate of an air change per hour is as follows. Maximum permitted number of particles m³.

Meeting Class 100 standards using the low-end air change recommendation 240hour inside a 12 x 12 x 7 3302 mm x 3302 mm x 2134 mm cleanroom with 1008 cu. Ad The Only Fully Integrated Modular Solution With Sterile Air Filtration.

Role And Calculation Of Air Changes Per Hour In Clean Room Area Pharmaceutical Guidelines

Iso Standard Clean Room Information

How Many Air Purifiers Do I Need One For Every Room Really

Clean Room Classifications Iso Standards Quotes 48 Hours

Clean Room Classifications Iso Standards Quotes 48 Hours

This Infographic Poster Portrays Environmental Impact Of Paper Used By Students With All Statistic Higher Learning Environmental Education Environmental Impact

Role And Calculation Of Air Changes Per Hour In Clean Room Area Pharmaceutical Guidelines

Iso 14644 Cleanroom Classification Classes And Requirements

Air Changes Per Hour Calculator Cfm Based Formula Examples

Air Background Environmental Guidelines Guidelines Library Infection Control Cdc

Why Is 90 Fpm Considered Standard For Cleanroom Airflow Pharmaceutical Engineering

Clean Room Classifications Iso Standards Quotes 48 Hours

52 Life Admin Tasks To Add To Your Planner This Year Planner Tips Planner Content Insurance

Iso 7 Clean Room Manufacturer Class 10000 Clean Rooms